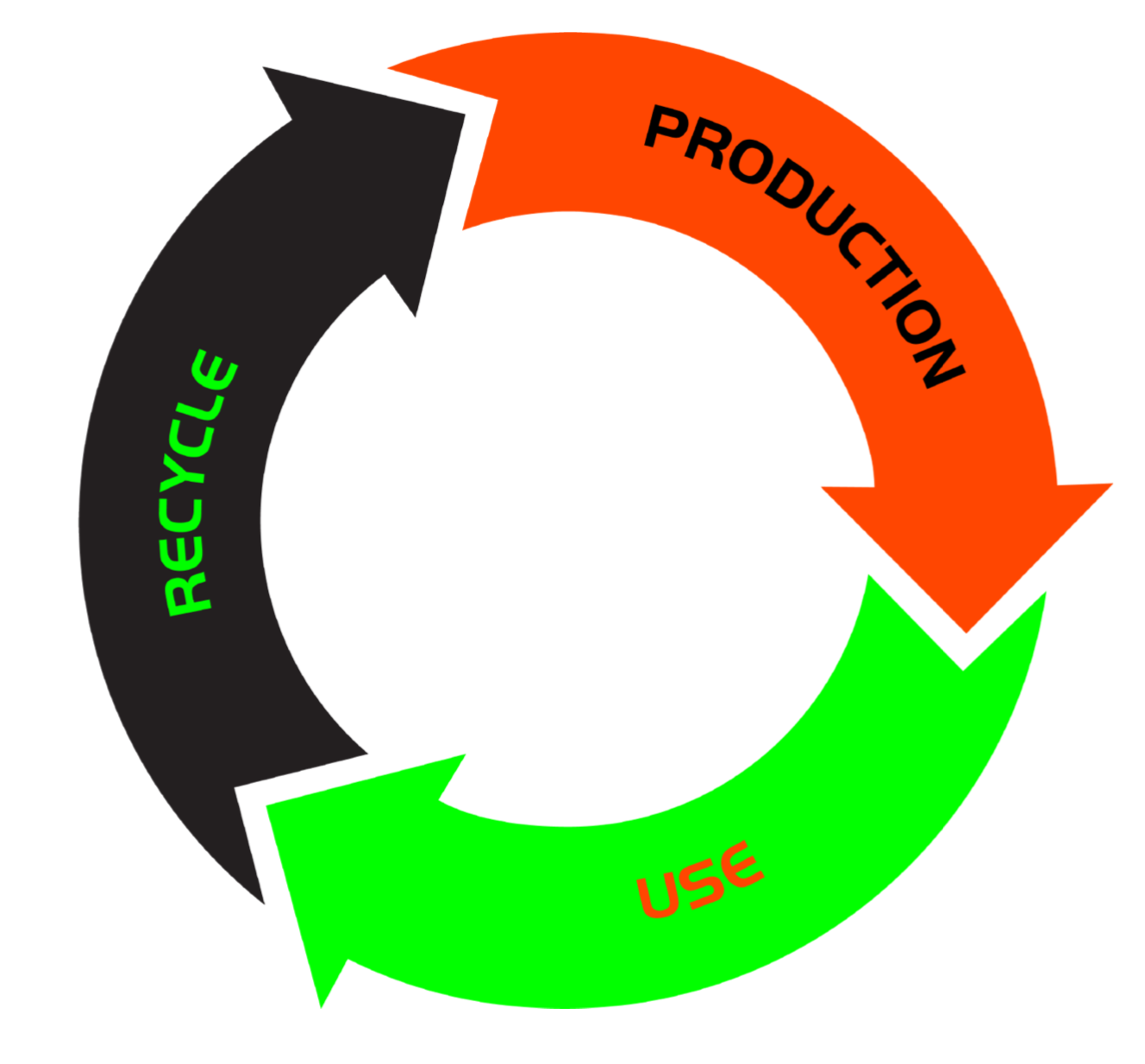

Gasification technologies enable the circular economy by re-purposing waste that cannot be disposed of through traditional recycling methods into clean and reusable products.

Our gasification systems are an environmentally responsible way of cleaning up the world’s dirtiest messes, with byproducts that add value and create revenue. The syngas created during processing can be used to produce energy to be used onsite or sold back to the grid. The glass-like slag can be used for road aggregate and other construction materials. Recycled metal ingots can be sold or repurposed for manufacturing. There’s no other waste disposal technology that solves industrial problems while creating new business opportunities.

Gasification Process

1 | Gasification

Waste enters the first chamber and is mixed with oxygen and steam heated to 1,500° Fahrenheit. 80% of the waste is turned into a mixture of gasses that are piped out of the system.

2 | Plasma Blasting

Material surviving gasification enters an 18,000° Fahrenheit plasma arc in the center of the container. Under that intense heat remaining trash is broken down to its atomic elements. Resulting gases are again captured and sequestered.

3 | Hazmat Capture

An electrically heated molten glass bath at the bottom of the cauldron traps any remaining hazardous material left over.

4 | Recycling

Molten inert glass is drawn out of the system and cooled into solid blocks that can be crushed and used for building materials.

Metals are captured and can be recycled into steel.

5 | Fuel Capture

Captured and compressed syngas—mostly carbon monoxide and hydrogen—are cleaned and converted to fuels like diesel or ethanol to produce electricity onsite or elsewhere.